我中心张旭辉(第一作者)和于文慧老师(通讯作者)、郑宏宇教授(通讯作者)在中科院1区TOP期刊Virtual and Physical Prototyping发表文章“Influence of erbium addition on the defects of selective laser melted 7075 aluminum alloy”。

高性能轻质合金对绿色制造、可持续发展具有重要意义。其中,7×××系列铝合金因其低密度、高比强度和良好的耐腐蚀性而在航空航天、汽车和军事工业中得到广泛应用。近年来,各行业对复杂、一体化产品的需求越来越高,传统制造工艺也逐渐显示出其局限性。选择性激光熔化(SLM),是金属3D打印的主要手段,已经成为一种加速材料创新的关键技术。SLM可以成形高致密度、低缺陷的4xxx铝合金,其中AlSi10Mg和Al-12Si合金已经实现了工程应用。航空航天领域要求更高强度和耐高温的铝合金材料,如7xxx (Al-Mg-Cu-Zn)铝合金,但是由于糊状凝固特点和高热裂倾向,高强度铝合金的SLM成形受到凝固裂纹的限制。仅通过工艺参数优化难以满足合金材料成形性的要求,因此有必要对7xxx铝合金粉末进行成分改性从而抑制凝固裂纹,提高SLM成形合金的综合性能。

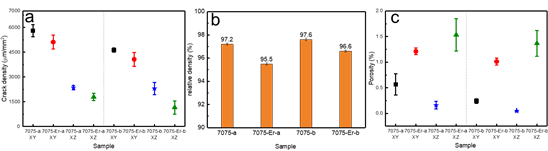

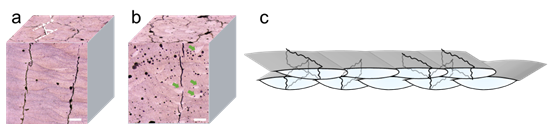

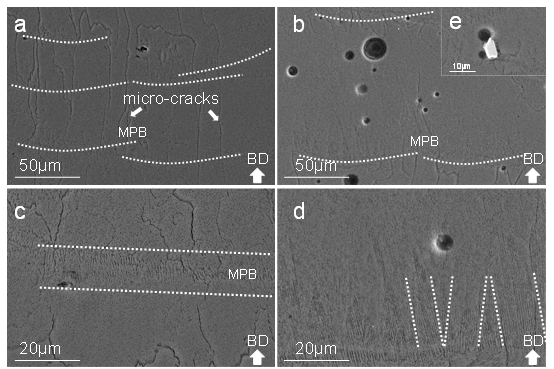

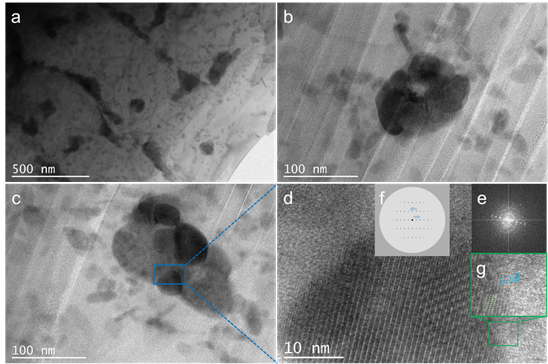

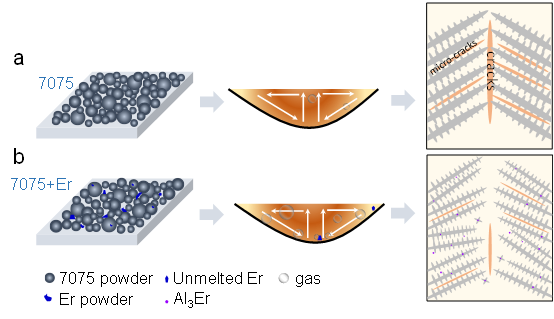

本文采用Er对7075铝合金进行改性,研究发现,Er可以显著降低7075打印件的裂纹倾向,但是同时气孔率增加,结合扫描测量每层旋转67°,裂纹的分布如图2c所示。从SEM图可以看出经过Er变质后,熔池内微裂纹明显减少,晶粒尺寸也得到细化。TEM图可以看到亚微米和纳米尺寸的含Er颗粒,并确认为Al3Er颗粒,这对晶粒细化和裂纹减少起到重要作用。最后提出Er对裂纹和气孔影响的作用机制,如示意图所示。

图1 裂纹密度、相对密度和气孔率分布

Figure 1. Crack density at transverse XY and longitudinal XZ plase (a), Relative density (b), and Porosity at transverse XY and longitudinal XZ plase (c) of samples with different treatments.

图2 光学显微图片及裂纹分布示意图

Figure 2. Optical isometric macrographs of (a) Sample 7075-b, and (b) Sample 7075-Er-b. (c) the schematic illustration of crack distribution corresponding to the layer-by-layer 67° rotation scanning strategies. Scale bar in a and b is 100 μm. An approximate 70° angle between neighbouring cracks is marked by the dashed line in a. Green arrows indicate the bright molten pools with fewer defects.

图3 SEM 图

Figure 3. SEM images of XZ plane in (a, c ) Sample7075-b and (b, d) Sample7075-Er-b. (e) Magnified SEM image showing white particles in XZ plane.

图4 TEM图

Figure 4. TEM microstructural characterization. (a) Low magnification TEM images taken from 7075-Er-b, showing the same type of particles with the ones in Figure 9, (b-c) Er containing particles of high magnification, (d) the corresponding HRTEM of the particle marked in c. The insets e and f are the experimental and stimulated FFT images, respectively. The enlarged inset g shows the coherency between the particle and the matrix.

图5 Er在粉末中分布及在熔池中演化示意图

Figure 5. Schematic illustration of how Er modified 7075 powders are different from the as-received 7075 powders.