Ali Naderi Bakhtiyari, a PhD Candidate of CALM (first author), Professor Yongling Wu and Professor Hongyu Zheng (corresponding authors), published a paper entitled “Laser machining sapphire via Si-sapphire interface absorption and process optimization using an integrated approach of the Taguchi method with grey relational analysis” in Journal of Materials Research and Technology.

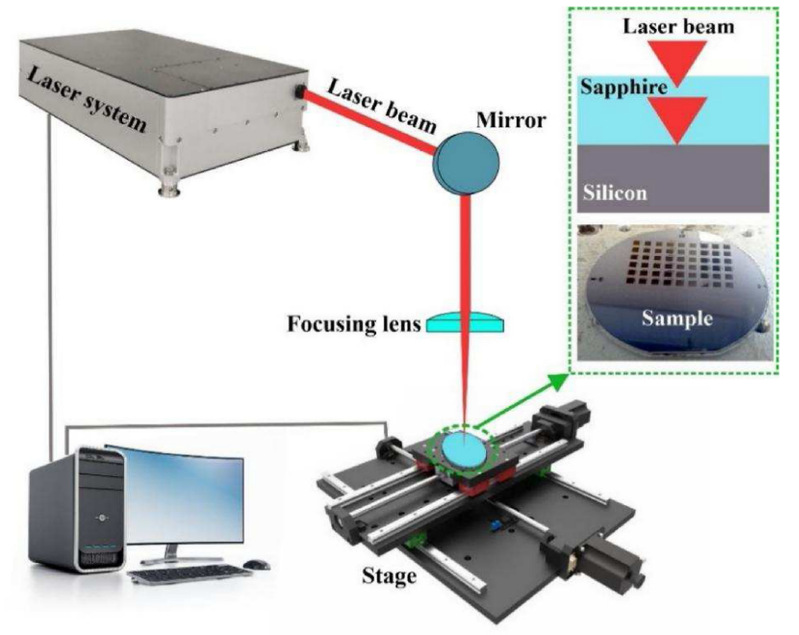

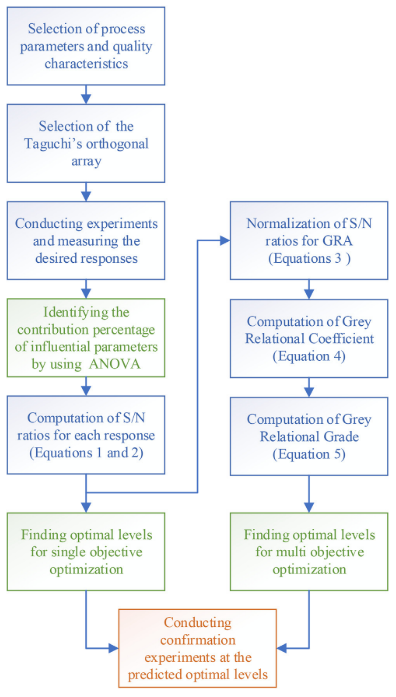

Laser machining of sapphire faces challenges due to the low laser beam energy absorption. A silicon (Si) plate contacting the rear surface of the sapphire substrate was used as an absorptive material to improve the laser absorption and affect material removal from the rear surface. A near-infrared laser with a wavelength of 1030 nm and pulse duration of 2 ns was focused at the interface, causing Si ablation and generation of a plasma plume with immense recoil pressure. The proposed approach for sapphire machining via enhanced laser absorption at the Si-sapphire interface is illustrated, and a probable material removal mechanism is discussed. Effects of processing parameters on machining depth and surface roughness were investigated using Taguchi L27 orthogonal array design and analysis of variance (ANOVA). It is found that repetition rate has the most significant effect on the machining performance characteristics, among other parameters. Furthermore, a multi- objective optimization was performed to optimize the process by integrating the Taguchi method with Grey Relational Analysis (GRA). The maximum machined depth of 59.1 mm and the minimum surface roughness of 0.145 mm were obtained by conducting confirmation tests at the optimal settings. The optimal processing parameters were obtained corresponding to the repetition rate of 1000 kHz, laser fluence of 1.2 J/cm2, hatching distance of 0.01 mm, scanning speed of 1000 mm/s, and single pass. The integrated Taguchi and GRA methodology offers an alternative for optimizing laser machining processes.

Fig. 1 The experimental setup for the laser machining of sapphire via Si-sapphire interface absorption.

Fig. 2 The procedure of single- and multi-objective optimizations using the Taguchi method and GRA.