Wang Chengjin, a postgraduate student of CALM (first author), Dr. WANG Zhiwen (corresponding authors) and Professor ZHENG Hongyu, published a paper entitled “Influence of focus positions on underwater femtosecond laser dicing of silicon wafer” in Journal of Manufacturing Processes (doi.org/10.1016/j.jmapro.2023.02.060).

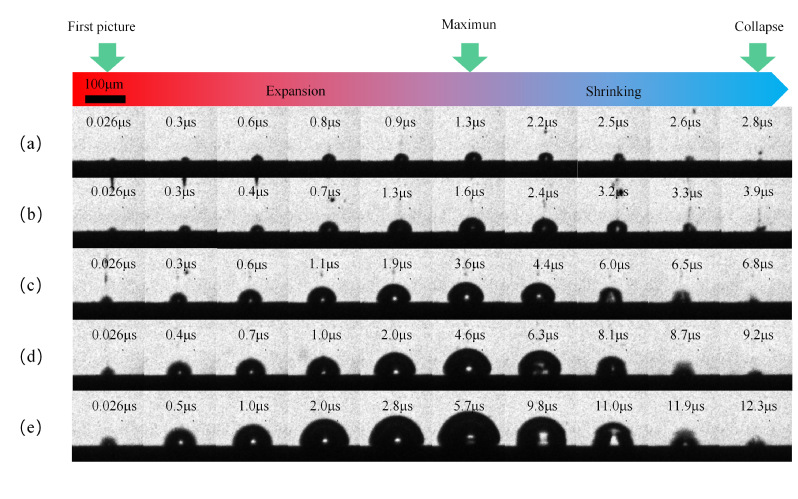

This paper investigates the effects of laser-induced bubbles on the surface morphology of silicon wafer at three focus positions: above the focus(positive-defocus), at the focus and below the focus (negative-defocus). Firstly, the behavior of the bubbles is observed from both the side view and top view of the laser ablation process at the three focus positions. Next, time-resolved shadowgraph images were used to examine evolution of the cavitation bubbles. The experimental results show that laser positive-defocus machining was accompanied by many bubbles, which aggregated to form a large bubbles barrier on the silicon wafer surface and disturbed the subsequent laser beam, and resulted in poor surface morphology of the groove. Laser negative-defocus machining produced few bubbles that moved in the opposite direction of laser scanning. The bubbles did not interfere with the subsequent laser pulses and showed little effect on the surface morphology of the machined groove. Compared to the laser machining at focus, the laser negative-defocus machining increased the groove depth by 88.61%, groove aspect ratio by 45.65%, cavitation bubbles size by 65.64%, and cavitation bubbles lifetime by 80.08%. The results show that the negative-defocus machining method has application prospects in underwater laser machining.

Fig 1. Evolution of the cavitation bubbles after laser ablation of silicon in deionized water: (a) 200 μm, (b) 100 μm, (c) 0, (d) −100 μm and (e) −200 μm.