Associate Professor Ashish Yadav, Professor WU Yongling & Professor ZHENG Hongyu published an article entitled “Wearable strain sensors: state-of-the-art and future applications” in Materials Advances.

Wearable strain sensors have drawn massive awareness in various studies and industrial fields. The growing suitability and adaptability of such systems have increased the demand for developing instruments with improved aspects and packaging required to investigate biointegrated gadgets, electronic skins, wearable wellness care techniques, and smooth robotics. Despite the outstanding performance, there are enormous challenges in the production of significant fundamental enrichments to the latest optical, mechanical, electrical, and sensing modalities and developing these for precise detection needs. Given all these demanding challenges, state-of-the-art wearable strain sensor technology is evolving towards a roadmap for exploring next level generation innovations and breakthroughs in nanotechnology, and flexible strain sensors incorporate the virtues of stretchability, high detection power, and several other features. Skin attachable wearable devices are developing as a tremendously attractive area due to their capable applications in the fields of artificial intelligence, human machine systems, and healthcare tools. To understand and explore wearable strain sensors, this brief review describes aspects of flexible wearable strain sensing systems along with their challenges and prospects.

Fig. 1 Potential state-of-the-art applications of wearable strain sensors.

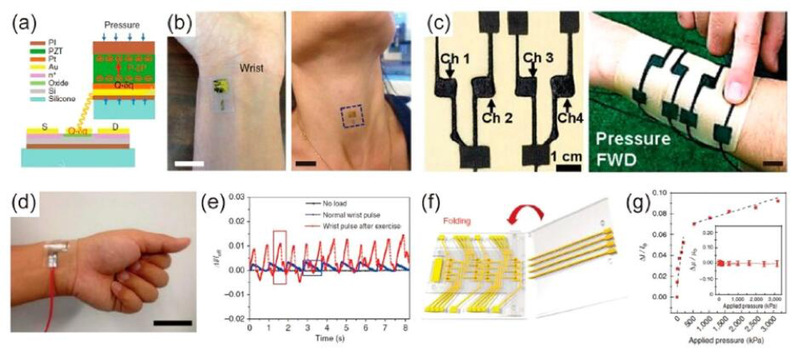

Fig. 2 Wearable pressure sensing gadgets. (a) A schematic diagram of the cross-section of the pressure sensor and its contacts in an accompanying transistor. (b) The pressure sensor positioned on a wrist and neck to measure instantaneous variations in blood pressure . (c) Printed pressure sensor mounted on a commercially available elastomeric patch. The arrays of the sensor consist of four channels of pressure sensors. (d) The skin-mounted sensor directly above the artery of the wrist (scale bar 3 cm). (e) The heartbeat is measured by sensing the physical force under healthy and exercising conditions (f) A picture representation of pressure-sensitive graphene FETs. (g) A plot of changes in normalized drain current versus pressure applied on the device

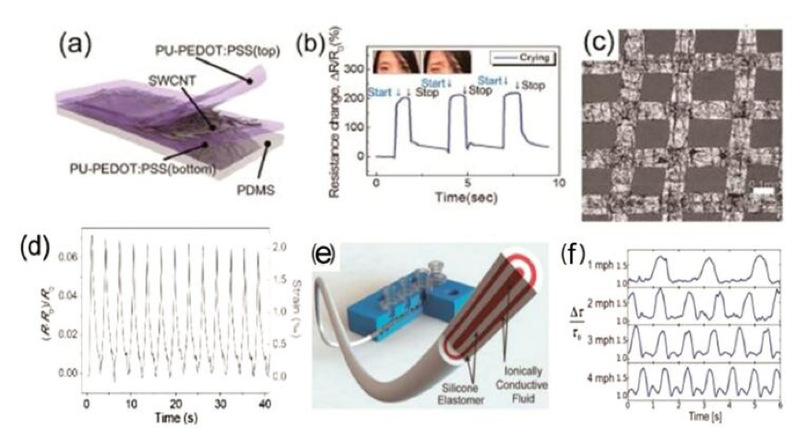

Fig. 3 Some examples of wearable strain sensors: (a) schematic cross-sectional diagram of the strain sensor comprised of 3-layers stacked in a nanohybrid structure. (b) Time-dependent resistance variations DR/R0 of the sensors (c) Optical micrograph of a graphene woven fabric’s relative change of resistance. (d) Relative resistance variation between 0% and 0.2% strain. (e) Representation of the multicore–shell printing procedure for a fiber-type capacitive strain sensor. (f) Normalized decay-time response of the sensor.