TIAN Wentao, a postgraduate student of CALM (first author), Dr. WANG Zhiwen (corresponding authors) and Professor ZHENG Hongyu, published a paper entitled “Effects of bubble behaviors in femtosecond laser machining of silicon wafer in liquids” in Journal of Manufacturing Processes (doi.org/10.1016/j.jmapro.2022.09.024).

In this article, the effects and mechanism of how bubble behaviors would affect liquid-assisted femtosecond laser cutting of silicon wafer are investigated. There are two kinds of bubbles generated during laser ablation in liquids, including the cavitation bubbles and the persistent bubbles. First, evolutions of the laser-induced cavitation bubbles are recorded by time-resolved shadowgraph imaging. The cavitation bubbles are shown to cause the defocusing effect on subsequent pulses, resulting in non-uniform ablated microgrooves. To improve the microgrooves morphology, the time interval between adjacent pulses is adjusted on basis of lifetime of the cavitation bubbles. The defocusing effect becomes alleviative when the time interval exceeds 100 μs. Next, the persistent bubbles are induced after the collapse of the cavitation bubbles and whose behaviors are studied. The results show that drastic explosions occur once the laser interacts with the persistent bubbles covered on the microgroove, and cause detrimental effects on surface morphology. The ethanol solution is chosen to improve surface wettability on basis of the dwell property of the persistent bubbles. Finally, the shielding effect of the persistent bubbles for incoming laser pulses is studied, which shows a decrease in the microgroove depth by 53 % in the 2 wt.% ethanol solution. This work illustrates how the bubbles affect the cutting of silicon wafer under liquid, and how uniform microgrooves with fine surface morphology are achieved by utilizing the bubble behaviors.

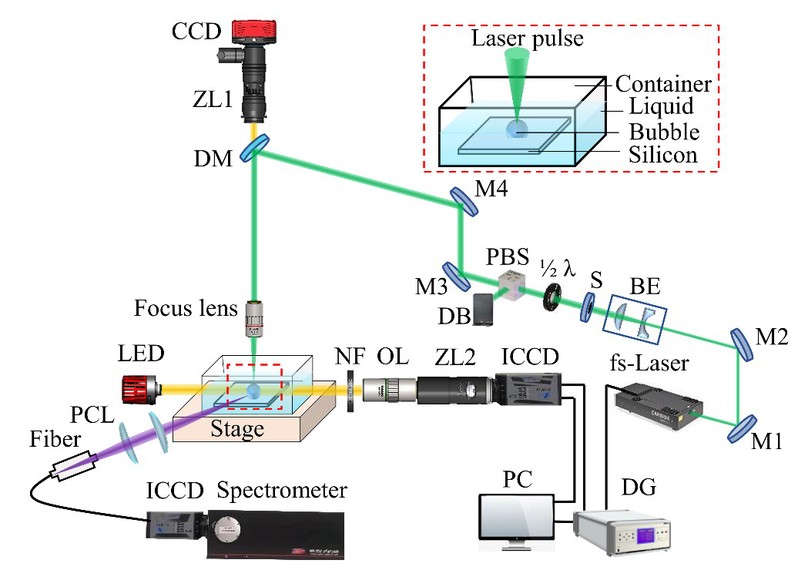

Figure 1. Schematic diagram of the experimental set up