Dr. YU Wenhui and Professor ZHENG Hongyu published a paper entitled “Recent progress on microstructure manipulation of aluminium alloys manufactured via laser powder bed fusion” in Virtual and Physical Prototyping (Q1, TOP journal, IF: 10.962).

Laser powder bed fusion (LPBF) is a promising additive manufacturing technique which allows layer-by-layer fabrication of metallic powders. Distinguished thermal dynamics result in microstructure of intrinsic features. The article aims to provide a thorough insight into the solidification fundamentals and the microstructural tailoring during LPBF. Growing attention has been drawn in the uptake of LPBF for the fabrication of aluminium alloys. The thermal dynamics of LPBF allows rapid melting and solidifying of powder materials and the subsequent intrinsic heat treatment. Typical microstructure includes columnar grains along the building direction and strong crystallographic texture, which results in anisotropy in the mechanical properties of the parts. Grain refinement resulting in more fraction of equiaxed grains favor the mechanical performance. For aluminium alloys with low strength, the major study on near eutectic Al–Si alloys with good printability was focused on processing parameters previously. Recently growing number of studies were performed the columnar to equiaxed transition to achieve high UTS and isotropy. Grain refining by inoculants, introduction of reinforced aluminium matrix composite, and alloying with Ni and Cu elements were explored. For moderate strength Al–Mg alloys, solidification crack was mainly eliminated by Sc and/or Zr alloying. A bimodal microstructure was reported and tailored by parameter manipulation. For high strength Al–Cu and Al–Zn–Mg alloys, three approaches were attempted to refine the grain and improve the feasibility of LPBF: (1) optimizing parameters by extremely high or low energy input, substrate preheating and supportive structure construction; (2) narrowing down the freezing range; (3) inoculants treatments. For future research prospects, manipulation of solidification process especially heterogeneous nucleation will be increasingly promising for aluminium applications via LPBF fabrication. Although various elements or ex situ inoculants have been studied, how to achieve a uniform distribution of nuclei in the melt pool and to increase the nucleation efficiency is still challenging. To solve this issue, the solidification behavior must be thoroughly understood as the melt pool exists locally within very short time. Materials design for LPBF is also vital for a wider application. The solidification path of these newly designed materials requires intensive research.

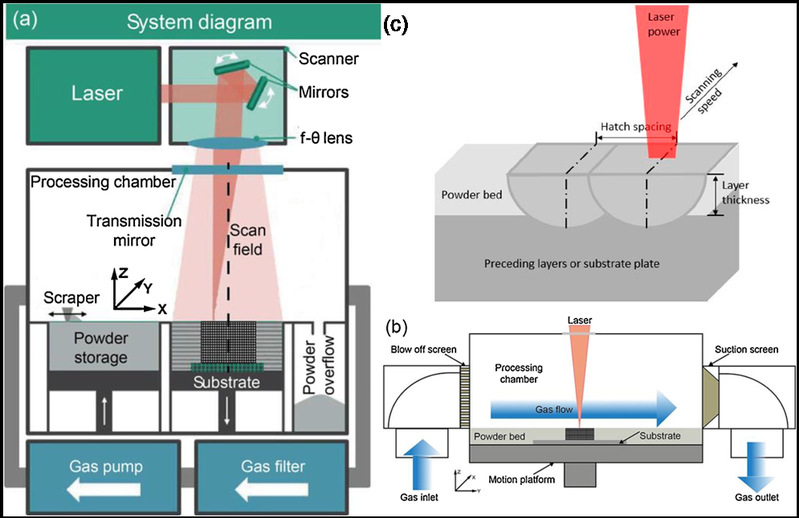

Figure 1. Schematic of (a) a typical LPBF machine, (b) gas circulation system, and (c) LPBF process parameters.

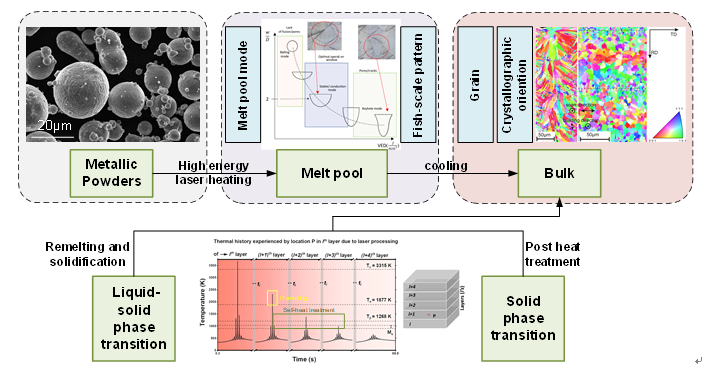

Figure 2. The illustration of the as-built microstructure formation.

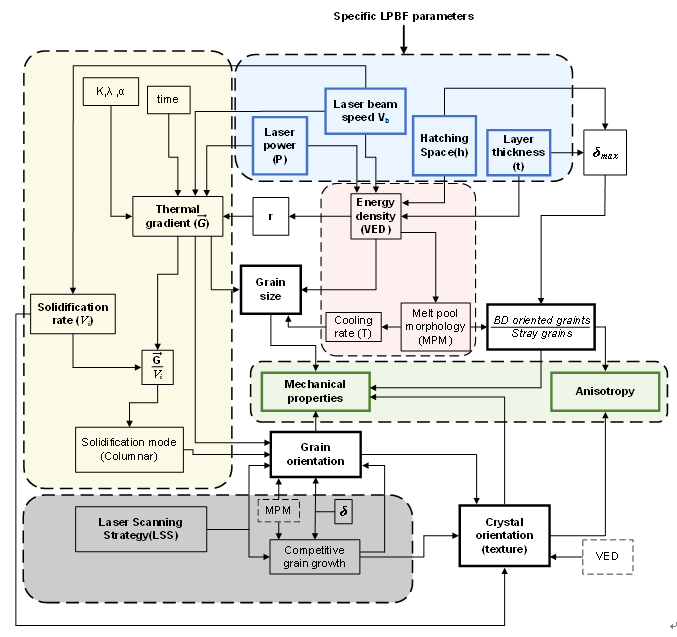

Figure 3. Interactions between LPBF parameters-microstructure-properties.