Dr. ZHU lihua and Professor ZHENG Hongyu, published a paper entitled “A new analytical model to predict residual stress induced by ultrasonic shot peening (10.1016/j.ijmecsci.2022.107430)” in International Journal of Mechanical Sciences.

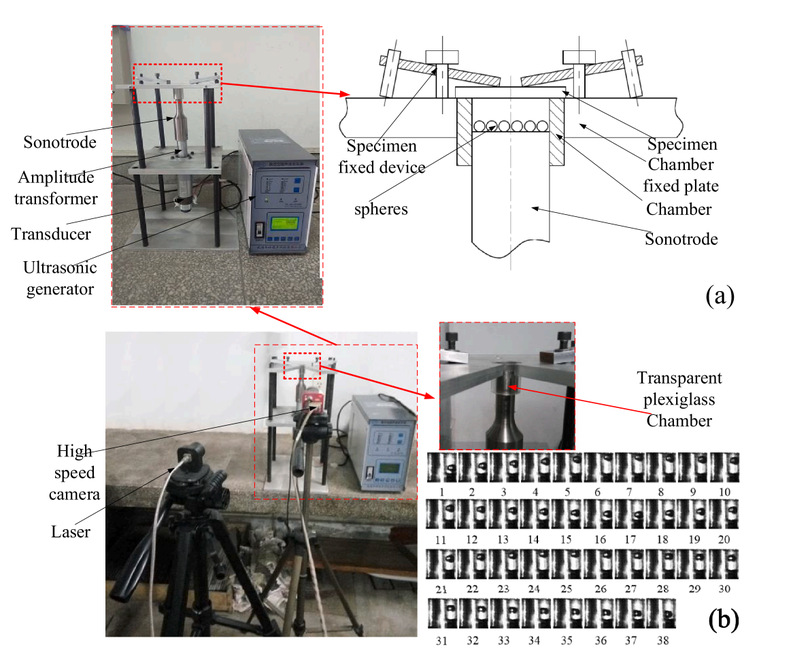

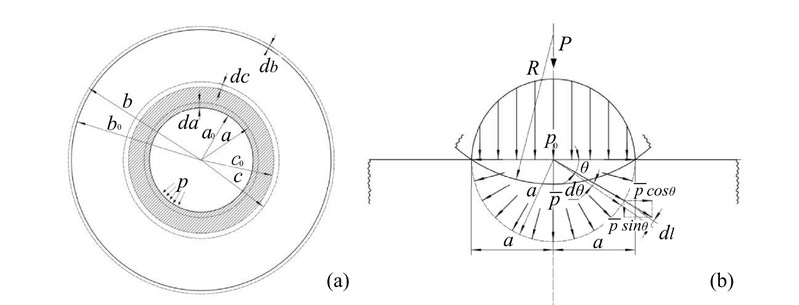

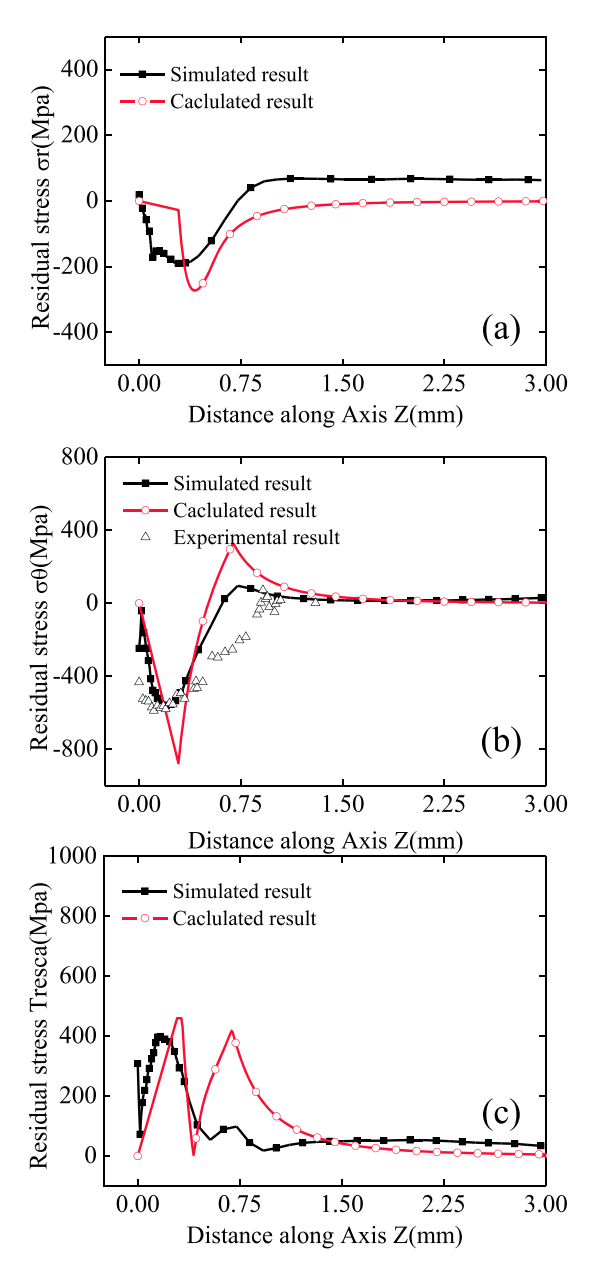

In this paper, a new analytical model of ultrasonic shot peening (USP) that can predict the impact velocity and the residual stress distribution was proposed and verified by experiments and simulations. The motion law of a single sphere during USP and effect of ultrasonic vibration on restitution coefficient are analyzed and a formula that can estimate the rebound velocity of the sphere after collision with the ultrasonic sonotrode using initial velocity, ultrasonic amplitude and frequency was proposed. Then, an analytical model to predict the impact velocity of the spheres was proposed and verified by high-speed camera observation. Besides, based on Hertz contact theory and Hill’s elastic-plastic spherical shell expansion theory, the conversion between hydrostatic pressure and Hertz pressure was realized. Then, a new analytical model that can predict the deformation extent, stress variation and residual stress distribution of the ideal elastic-plastic plate impacted by a rigid sphere with a certain velocity was proposed and verified by finite element simulations. Based on the above two models and the results of two different stress superposition methods, an analytical model that can estimate the impact velocity and the residual stress distribution of the USP-treated plate surface layer with the USP process parameters and material properties of the sphere, sonotrode and treated material was proposed and experimentally verified. The calculated results are consistent with the experimental results well.

Fig. 1 (a) The USP apparatus and (b) the motion observation of the sphere in the plexiglass chamber by a high speed camera.

Fig. 2 (a) Hill’s elastic-plastic spherical shell expansion and (b) Conversion between hydrostatic pressure p and Hertz pressure.

Fig.3 The calculated result, simulated result and experimental result of the residual stress distribution of multiple impacts of a single sphere at the same position