Dr. YU Wenhui (first author) and Professor ZHENG Hongyu (corresponding authors), published a paper entitled “Processing and characterization of crack-free 7075 aluminum alloys with elemental Zr modification by laser powder bed fusion” in Materials Science in Additive Manufacturing.

In this study, aluminum alloy (AA) 7075 with and without Zr modification was additively manufactured by LPBF. Processing parameters of laser power and scanning speed, resulting in various volumetric energy density (VED), were experimentally determined to produce crack-free components. How the crack density and porosity vary with VED were investigated ,the microstructures changes in the molten pool and the mechanism of Zr element evolution were revealed. The results indicate that 1 w.t.% addition of elemental Zr in AA7075 led to lower crack density and crack-free components were obtained under high VED. Fine equiaxed grains were formed at the bottom of the molten pool boundary due to the existence of Al3Zr compound, which favored the nucleation of aluminum grains and elimination of cracks. Spherical pores in the Zr-modified AA7075 increased due to the deterioration of fluidity by unmelted particles. By optimizing parameters, crack-free AA7075 parts with low porosity can be manufactured through LPBF with Zr addition.

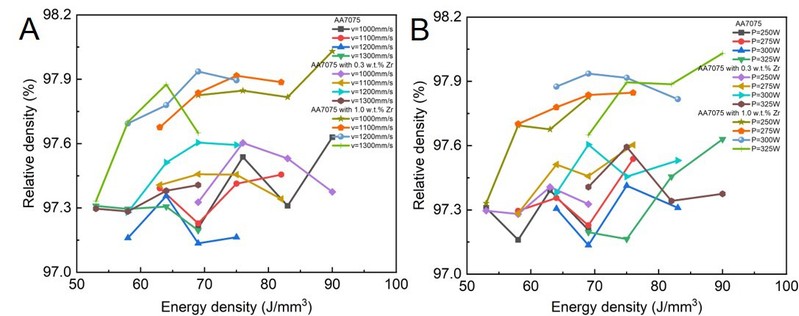

Figure 1. Relative density of the LPBF AA7075 of different chemical compositions under various (A) laser power and (B) scanning speed.

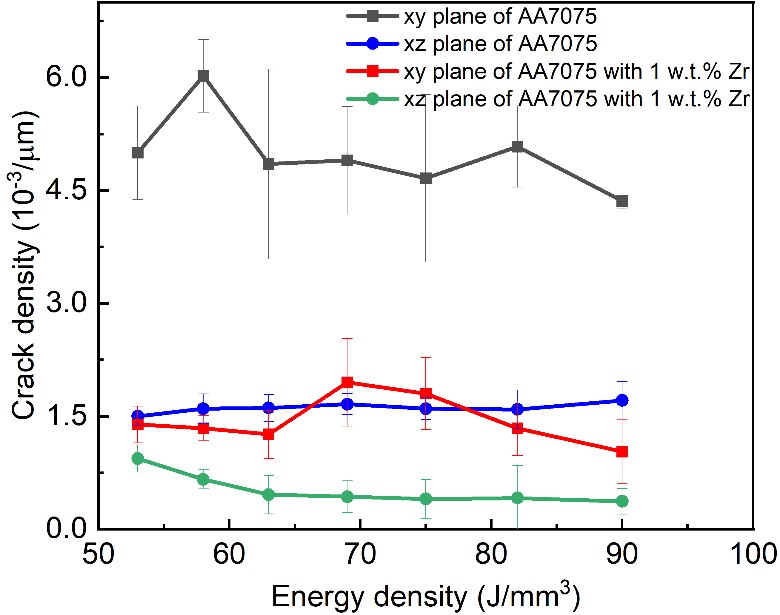

Figure 2. Crack density on xz and xy planes of the LPBF AA7075 and 1 w.t.% Zr-modified AA7075 under different VED.

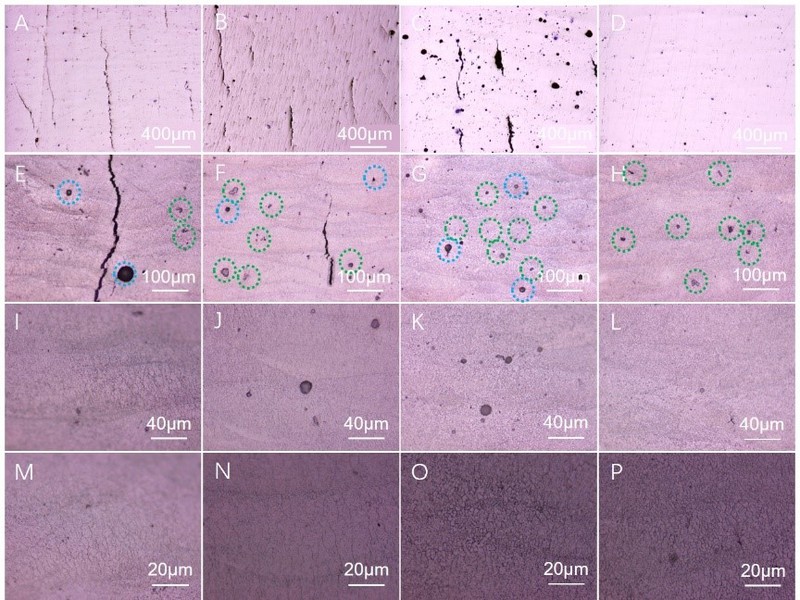

Figure 3. Representative microstructure of samples with scanning speed 1100 mm/s and laser power (A, E, I, M) 250 W , (B, F , J, N) 275 W , (C, G, K, O) 300 W , and (D, H, L, P) 325W.

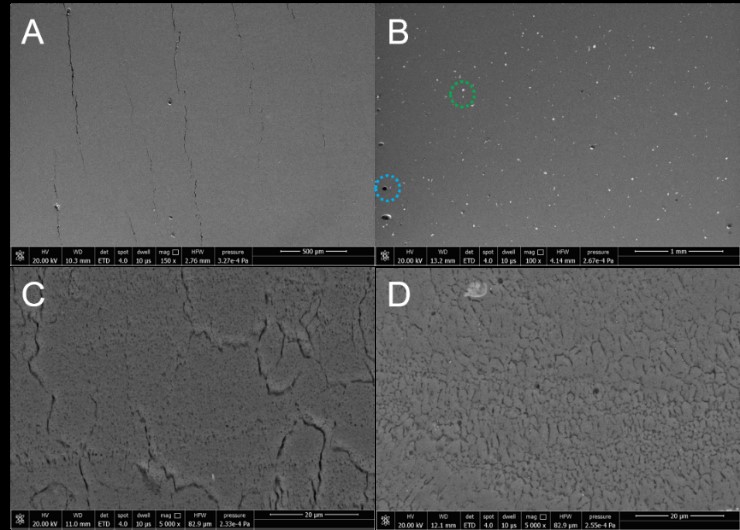

Figure 4. SEM images of samples with scanning speed 1100 mm/s and laser power 325 W .

(A, C) AA7075. (B, D) 1 w.t.% Zr-modified AA7075.

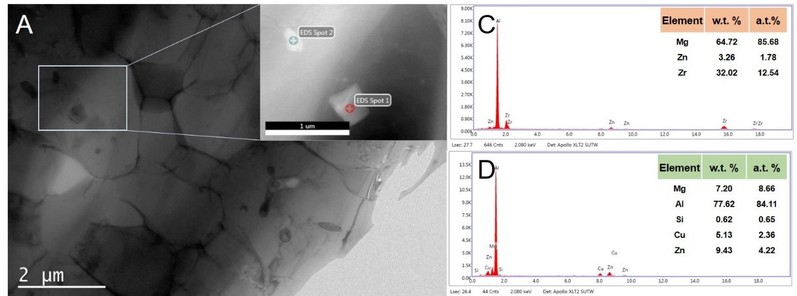

Figure 5. TEM images of sample with scanning speed 1100 mm/s and laser power 325 W . The inset was taken in STEM mode, in which EDS results were measured.