Dr. Wang Zhiwen (corresponding author) and Zhang Longda (undergraduate student in SDUT), published a paper entitled “Elman Neural Network Based Prediction of Microsecond Laser Induced Coloring on Stainless Steel” in Chinese Journal of Lasers.

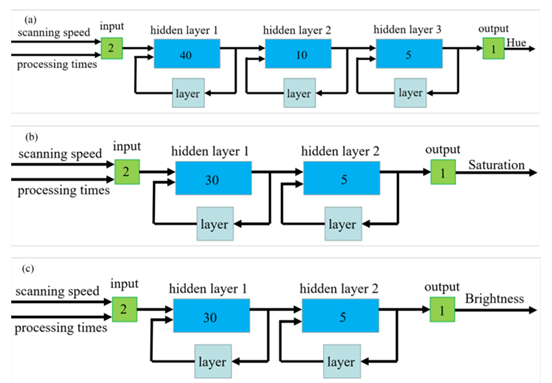

Laser metal coloring technology has the advantages of pollution-free, simple operation and high degree of automation, and has broad application prospects in the field of metal coloring. In order to further study the microsecond laser metal (304 stainless steel) coloring technology, the mechanism of microsecond laser induced coloring on 304 stainless steel was discussed in this paper, and the Elman neural network was established to predict the laser coloring effect under given processing parameters.

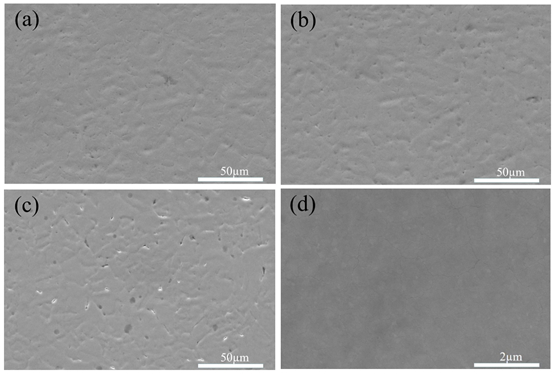

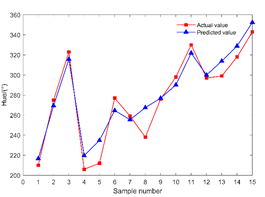

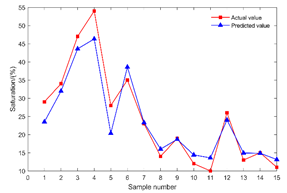

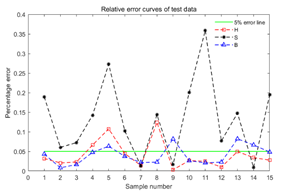

The surface morphology and elemental composition of the color patches were analyzed by using scanning electron microscope (SEM) and X-ray energy spectrometer.Coloring mechanism of 304 stainless steel induced by the microsecond laser is believed to be the color of the oxide layer and the film interference effect. Considering the difficulty of quantitative analysis on coloring effect based on coloring mechanism, it can be proposed that using the Elman neural network to predict HSB value of color patches for the given microsecond laser parameters. The comparison between the prediction results and test values showed that the established Elman neural network has good prediction accuracy.

Fig. 1 Microscopic surface structure of color patch. (a) yellow; (b) orange-red; (c) blue; (d) amplified blue surface

Fig.2 Structure of neural network. (a) net_H; (b) net_S; (c) net_B

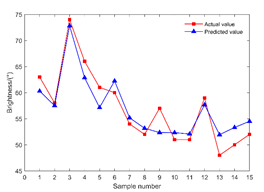

Fig.3 Comparison of actual and predicted Hue Fig.4 Comparison of actual and predicted Saturation

Fig.5 Comparison of actual and predicted Brightness Fig.6 Relative error curves of test data