WANG Zhiwen, a lecturer of our center (first author) and Professor ZHENG Hongyu (corresponding author), published a paper entitled “The effect of laser in-situ induced graphene-like micro-texture on the friction and wear properties of ductile cast iron” in the Journal of Materials Research and Technology.

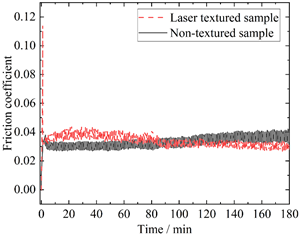

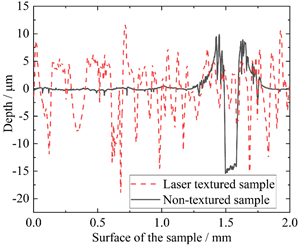

Picosecond fiber laser was subjected on surface of ductile cast iron to induce graphene-like micro-texture array and enhance the tribological properties. The in-situ fabrication process was carried out on the workpiece surface in parallel manner (Fig.1b) and the scanning speed can be up to 3 m/s. The laser textured samples exhibit low coefficient of friction and the anti-wear properties were improved significantly. Volume wear rate was reduced by 69.6±6.9%. The improved tribological properties are attributed to the combined effects of the increased surface hardness, improved heat dispersion property and entrapment of wear debris.

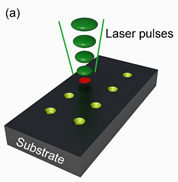

Fig. 1 Laser scanning strategy: (a) spot-by spot ablation; (b) one-directional scanning; (c) circular scanning.

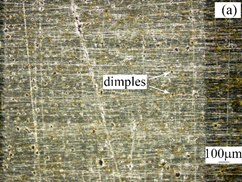

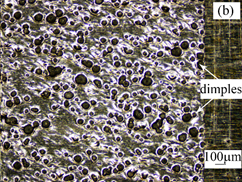

Fig. 2 Optical image of laser surface texturing: (a): with low laser energy irradiation; (b): with high laser energy irradiation

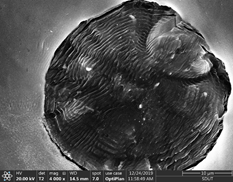

Fig. 3 SEM image of the dimple induced by laser irradiation on ductile cast iron

Fig. 4 Friction coefficient curves of laser textured and non-textured samples Fig. 5 Surface profile of laser textured and non-textured samples