Ali Naderi Bakhtiyari, a doctoral student of our center (first author) and Professor ZHENG Hongyu (corresponding author), published a paper entitled “Feasibility of artificial neural network on modeling laser-induced colors on stainless steel” in the Journal of Manufacturing Processes.

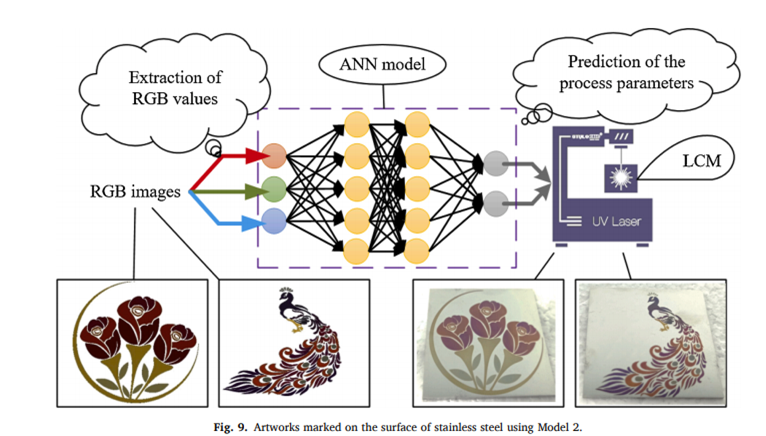

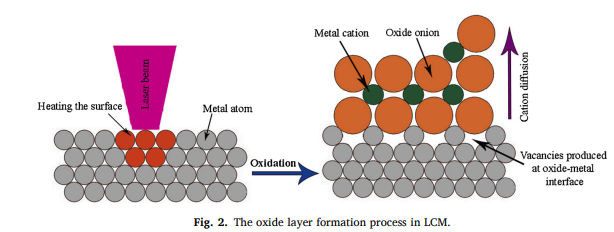

It is indicated that a certain RGB color can be obtained by specific processing parameters in Laser Color Marking (LCM). However, these parameters do not necessarily provide the same color in different laser systems. In most of the conducted studies on LCM, the focus is on the oxide layer formation mechanism, reflectance spectra, composition, and thickness of the oxide layer, which are ultimately controlled by various factors such as laser processing parameters, sample substrate properties, and ambient conditions. However, there is a lack of study on the quantitative relationship between processing parameters (as the main influential factor) and the produced RGB color in LCM. In this work, for the first time, we propose a method to quantitatively match the processing parameters and the RGB colors in LCM using the artificial neural network (ANN). In this regard, two models have been developed based on experimental data to predict the resultant RGB color and the proper processing parameters for a desired color, respectively.

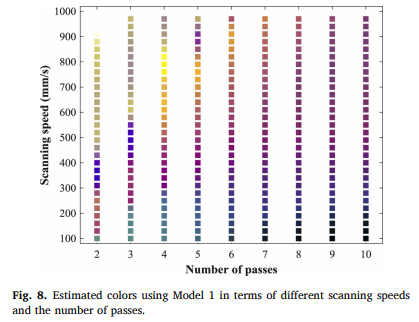

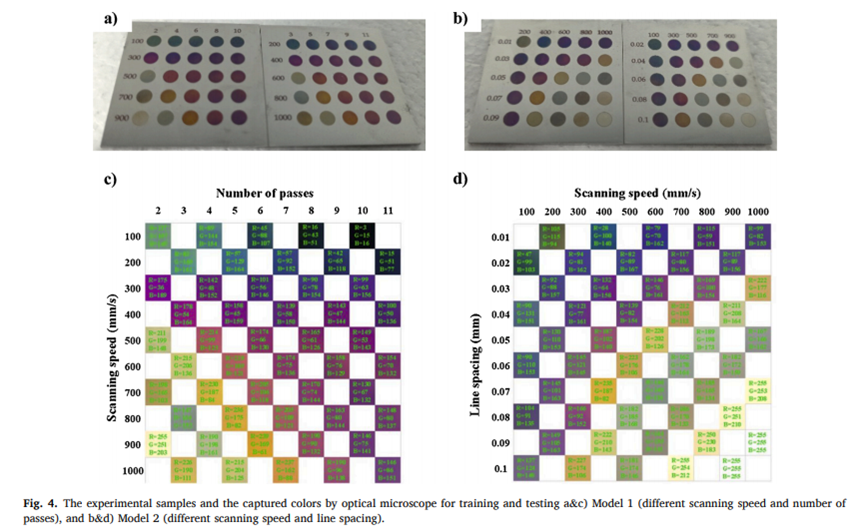

In this study, two ANN models were established to estimate the relationship between the operating parameters of the LCM process and the output colors. Model 1 is established to predict the color for the different number of passes and scanning speed. The purpose of Model 2 is to provide guidance for obtaining certain RGB values (colors) by estimating adequate line spacing and scanning speed. Both models are rained and tested based on different sets of experimental data. In total, 100 experiments were designed to achieve a wide range of colors, as shown in Fig. 4. The inputs (scanning speed and number of passes) and outputs (RGB values) of Model 1 are measured using the first set of experiment (Fig. 4a and c). The second set of experiment is used to define the inputs (RGB values) and the outputs (scanning speed and line spacing) of Model 2 (Fig. 4b and d). The other influential parameters were fixed so to focus on the effects of the studied parameters in both models.

In Fig. 8, Model 1 is used to estimate the resultant colors under various scanning speeds and the number of passes. This model provides the opportunity for the operator to estimate the generated colors under different processing parameters. It is clearly shown that the studied parameters had a noticeable influence on the produced colors.